Cultivation of Monoraphidium sp. on fruit peels to produce expedited lipids and carotenoids for the sustainable biorefinery

Research Articles | Published: 19 July, 2023

First Page: 556

Last Page: 565

Views: 3070

Keywords: Microalgae, Fruit peel waste, Biomass, Lipids, Carotenoids

Abstract

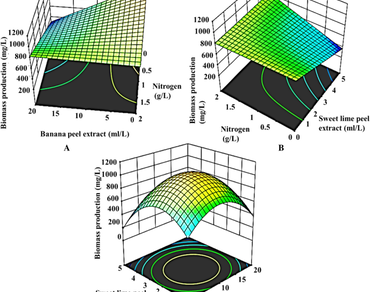

Microalgae-derived bioactive bioproducts are due to their potential application in pharmaceuticals and nutraceuticals. Nevertheless, the exorbitant cost of nutrients essential for microalgal cultivation is a significant obstacle to commercially feasible algal-mediated value-added compound manufacturing. Fruit waste like banana peel and sweet lime peels were used instead of traditional growing media in this investigation to cultivate Monoraphidium sp. These wastes are zero-value substances comprising essential nutrients and components to produce microalgae biomass. Response surface methodology (RSM) based on a central composite design (CCD) was used to analyze the optimization of fruit waste slurry with nitrogen content on biomass, lipids, and carotenoids production. When the Monoraphidium sp. was grown in 12.5 ml L−1 banana peel slurry (BPS) and 2.5 ml L−1sweet lime peel slurry (SLPS) with 1.5 g L−1 nitrogen (N), the most significant biomass yield of 1089 mg L−1, lipids of 14,362 RFU and carotenoids of 11.5 µg ml−1 were obtained. The TLC analysis revealed the presence of astaxanthin, regarded as a commercially established carotenoid. The results showed that these organic wastes could potentially serve as a sustainable, low-cost, and environmentally reliable alternative medium for the development of microalgae with boosted value-added compounds.

References

Agarwal A, Singh A, Banerjee BD, Rai MP, Mukherjee M (2021) Exotic hydrogel matrix as an efficient platform for sustainable production of biomass and lipid from Chlorella Sorokiniana. ACS Appl Bio Mater 4(8):6304–6315. https://doi.org/10.1021/acsabm.1c00570

Ahuja S, Roy A, Kumar L, Bharadvaja N (2020) Media optimization using Box Behnken design for enhanced production of biomass, β-carotene and lipid from D. salina. Vegetos 33:31–39. https://doi.org/10.1007/s42535-019-00079-4

Anahas AMP, Muralitharan G (2019) Central composite design (CCD) optimization of phytohormones supplementation for enhanced cyanobacterial biodiesel production. Renew Energy 130:749–761. https://doi.org/10.1016/j.renene.2018.06.110

Baskar V, Safia N, Sree Preethy K, Dhivya S, Thiruvengadam M, Sathishkumar R (2021) A comparative study of phytotoxic effects of metal oxide (CuO, ZnO and NiO) nanoparticles on in-vitro grown Abelmoschus esculentus. Plant Biosyst 155(2):374–383. https://doi.org/10.1080/11263504.2020.1753

Bhatia L, Jha H, Sarkar T, Sarangi PK (2023) Food waste utilization for reducing carbon footprints towards sustainable and cleaner environment: a review. Int J Env Res Pub He 20(3):2318. https://doi.org/10.3390/ijerph20032318

Calhoun S, Kamel B, Bell TA, Kruse CP, Riley R, Singan V, Kunde Y, Gleasner CD, Chovatia M, Sandor L, Daum C (2022) Multi-omics profiling of the cold tolerant Monoraphidium minutum 26B-AM in response to abiotic stress. Algal Res 66:102794. https://doi.org/10.1016/j.algal.2022.102794

Chandrasekhar K, Raj T, Ramanaiah SV, Kumar G, Banu JR, Varjani S, Sharma P, Pandey A, Kumar S, Kim SH (2022) Algae biorefinery: a promising approach to promote microalgae industry and waste utilization. J Biotech 345:1–6. https://doi.org/10.1016/j.jbiotec.2021.12.008

Chong JW, Khoo KS, Yew GY, Leong WH, Lim JW, Lam MK, Ho YC, Ng HS, Munawaroh HS, Show PL (2021) Advances in production of bioplastics by microalgae using food waste hydrolysate and wastewater: A review. Biores Technol 342:125947. https://doi.org/10.1016/j.biortech.2021.125947

Gao F, Teles I, Ferrer-Ledo N, Wijffels RH, Barbosa MJ (2020) Production and high throughput quantification of fucoxanthin and lipids in Tisochrysis lutea using single-cell fluorescence. Bioresour Technol 318:124104. https://doi.org/10.1016/j.biortech.2020.124104

Hara KY, Kageyama Y, Tanzawa N, Hirono-Hara Y, Kikukawa H, Wakabayashi K (2021) Development of astaxanthin production from citrus peel extract using X. dendrorhous. ESPR 28:12640–12647. https://doi.org/10.1007/s11356-020-11163-7

Kabir MT, Rahman MH, Shah M, Jamiruddin MR, Basak D, Al-Harrasi A, Bhatia S, Ashraf GM, Najda A, El-Kott AF, Mohamed HR (2022) Therapeutic promise of carotenoids as antioxidants and anti-inflammatory agents in neurodegenerative disorders. Biomed Pharmacother 146:112610. https://doi.org/10.1016/j.biopha.2021.112610

Kaha M, Iwamoto K, Yahya NA, Suhaimi N, Sugiura N, Suzuki K (2021) Enhancement of astaxanthin accumulation using black light in Coelastrum and Monoraphidium isolated from Malaysia. Sci Rep 11:1–9. https://doi.org/10.1038/s41598-021-91128-z

Khanra A, Srivastava M, Rai MP, Prakash R (2018) Applications of unsaturated fatty acid molecules derived from microalgae toward mild steel corrosion inhibition in HCl solution: a novel approach for metal-inhibitor association. ACS Omega 10:12369–12382. https://doi.org/10.1021/acsomega.8b01089

Khanra A, Vasistha S, Kumar S, Rai MP (2021) Cultivation of microalgae on unhydrolysed waste molasses syrup using mass cultivation strategy for improved biodiesel. 3 Biotech 6:1–14. https://doi.org/10.1007/s13205-021-02823-7

Kumar S, Kumar R, Diksha KA, Panwar A (2022) Astaxanthin: A super antioxidant from microalgae and its therapeutic potential. J Basic Microbiol 9:1064–1082. https://doi.org/10.1002/jobm.202100391

Kumari N, Sahani GK, Kumar S (2023) Growth of Chlorella Minutissima microalgae from fruit waste extract for biodiesel production. In: Srivsatava N, Mishara PK (eds) Basic research advancement for algal biofuels production. Springer, Singapore

Malakar B, Das D, Mohanty K (2022) Evaluation of banana peel hydrolysate as alternate and cheaper growth medium for growth of microalgae C. sorokiniana. Biomass Convers Bioref 30:1. https://doi.org/10.1007/s13399-022-03106-8

Mishra S, Singh S (2022) Organoleptic and morphological analysis of citrus peel powder. Asian Food Sci J 5:1–1. https://doi.org/10.9734/afsj%2F2022%2Fv21i11591

Nair A, Ahirwar A, Singh S, Lodhi R, Lodhi A, Rai A, Jadhav DA, Harish VS, Singh G, Marchand J (2023) Astaxanthin as a king of ketocarotenoids: structure, synthesis, accumulation bioavailability and antioxidant properties. Mar Drug 21(3):176. https://doi.org/10.3390/md21030176

Ratto F, Franchini F, Musicco M, Caruso G, Di Santo SG (2022) A narrative review on the potential of tomato and lycopene for the prevention of Alzheimer’s disease and other dementias. Crit Rev Food Sci Nutr 62(18):4970–4981. https://doi.org/10.1080/10408398.2021.1880363

Samuel PO (2015) Production of biogas from perennial and biennial crop wastes: peach palm and banana’s wastes as alternative biomass in energy generation and environmental sustainability. Am J Environ 4:79–89. https://doi.org/10.5923/j.ajee.20150504.01

Shenwari KA, Dhevagi P, Chitdeshwari T, Avudainayagam S (2018) Biosorption of cadmium from aqueous solutions by banana peel powder. Madras Agric J 10(1):1. https://doi.org/10.29321/MAJ.2018.000096

Yadav N, Singh DP (2021) Photosynthetic efficiency and compositional alterations in microalgae Chlorella vulgaris in response to changes in the pH condition. Vegetos 34(1):119–126. https://doi.org/10.1007/s42535-021-00186-1

Yadav K, Vasistha S, Nawkarkar P, Kumar S, Rai MP (2022) Algal biorefinery culminating multiple value-added products: recent advances, emerging trends, opportunities, and challenges. 3 Biotech 12(10):244. https://doi.org/10.1007/s13205-022-03288-y

Zhang L, Pei H, Chen S, Jiang L, Hou Q, Yang Z, Yu Z (2018) Salinity-induced cellular cross-talk in carbon partitioning reveals starch-to-lipid biosynthesis switching in low-starch freshwater algae. Biores Technol 250:449–456. https://doi.org/10.1016/j.biortech.2017.11.067

Author Information

Amity Institute of Biotechnology, Amity University, Noida, India